Challenge

A major aero-engine OEM faced significant manufacturing inefficiencies with their existing bearing housing design. The component featured 48 welded cast vanes, resulting in an unnecessarily complex assembly process that increased production costs and time. In an industry where the quality of every component affects operational efficiency, this suboptimal design needed urgent optimization.

Solution

Quest Global delivered an optimized bearing housing design that:

Implemented single-piece casting architecture to replace the complex 48-vane assembly

Validated structural integrity through comprehensive analysis aligned with OEM standards

Developed complete design documentation, including stress analysis and engineering drawings

Reduced aerodynamic wind steps in the annulus to enhance performance

Created manufacturing guidelines to ensure consistent production quality

Results – At A Glance

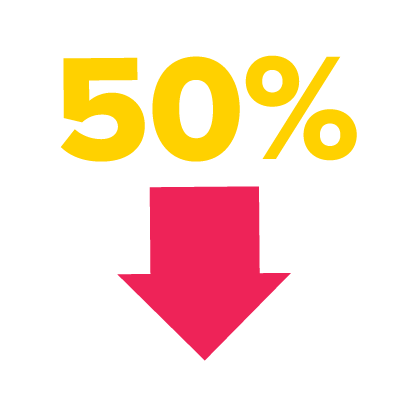

Achieved 50% reduction in manufacturing costs

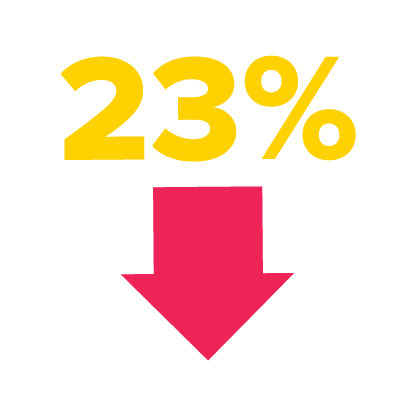

Decreased component weight by 23%

Improved aircraft fuel efficiency through enhanced aerodynamics

Met all redesign requirements 100% on-time and on-budget

Delivered all redesign requirements on schedule and within budget

Provided complete documentation package, including 3D models, stress reports, and manufacturing specifications