Challenge

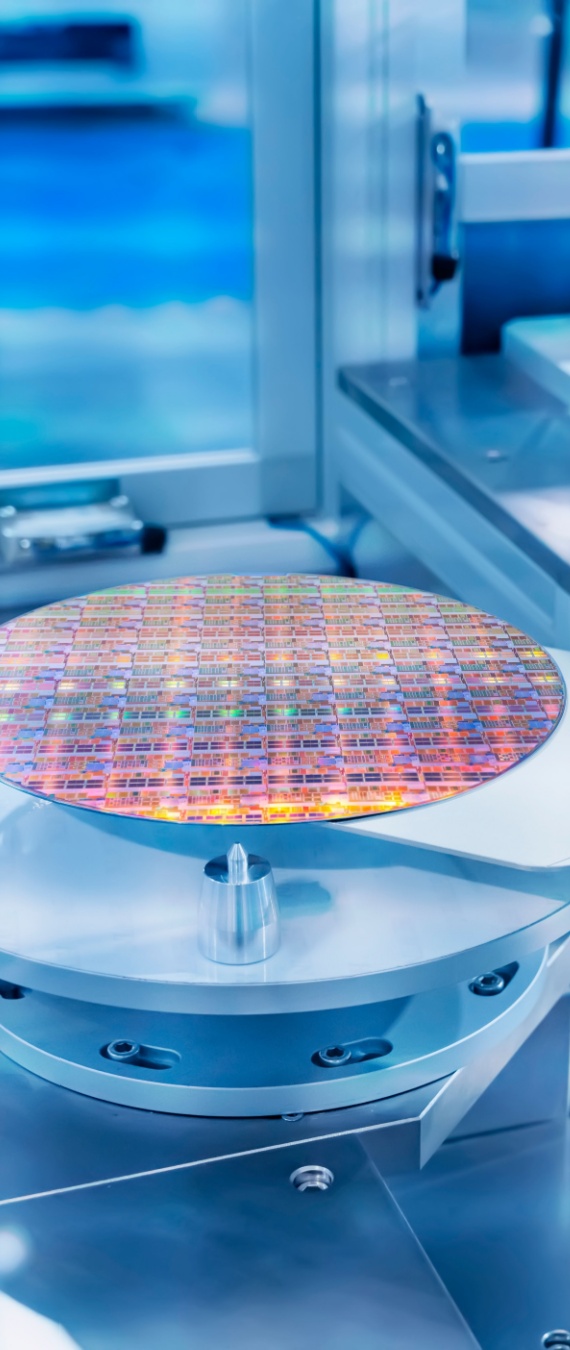

A semiconductor etch equipment OEM needed automation software for their 300mm wafer etch equipment. They required a complete software automation stack that would control their advanced etch equipment while maintaining strict adherence to SEMI standards. The OEM sought to adopt a field-proven new-generation equipment control platform for their etch equipment portfolio. The OEM also wanted to reduce the time to market their next-generation etch equipment.

Solution

Quest Global delivered an integrated equipment control solution leveraging the Quest Global Equipment Automation framework that:

Initiated the study of the etch equipment hardware components onsite and implemented device drivers to interface with the hardware devices

Developed custom protocol interfaces for mass flow controllers and endpoint detectors

Customized Quest Global Equipment Automation framework having full compliance to SEMI standards, including E4, E5, E30, E37, E39, E58, E84, E87, E90, E94, E116

Customized user interface of Quest Global’s Equipment Automation to cater to the needs of etch equipment and developed E95-compliant user interfaces with real-time wafer movement visualization

Implemented automated testing frameworks with CCS Envoy validation

Integrated the solution with hardware at the customer site and followed it with fab acceptance support, furthermore, enabling the customer’s focus on hardware development and optimization through complete software development ownership

Results – At A Glance

Reduced time-to-market by 70% by adopting Quest Global’s ready-to-deploy automation solutions

Controlled R&D costs by adopting per-equipment licensing

Passed factory acceptance testing at first go because of the high maturity of Quest Global’s Equipment Automation framework

Maintained high product quality across all fab deployments