Challenge

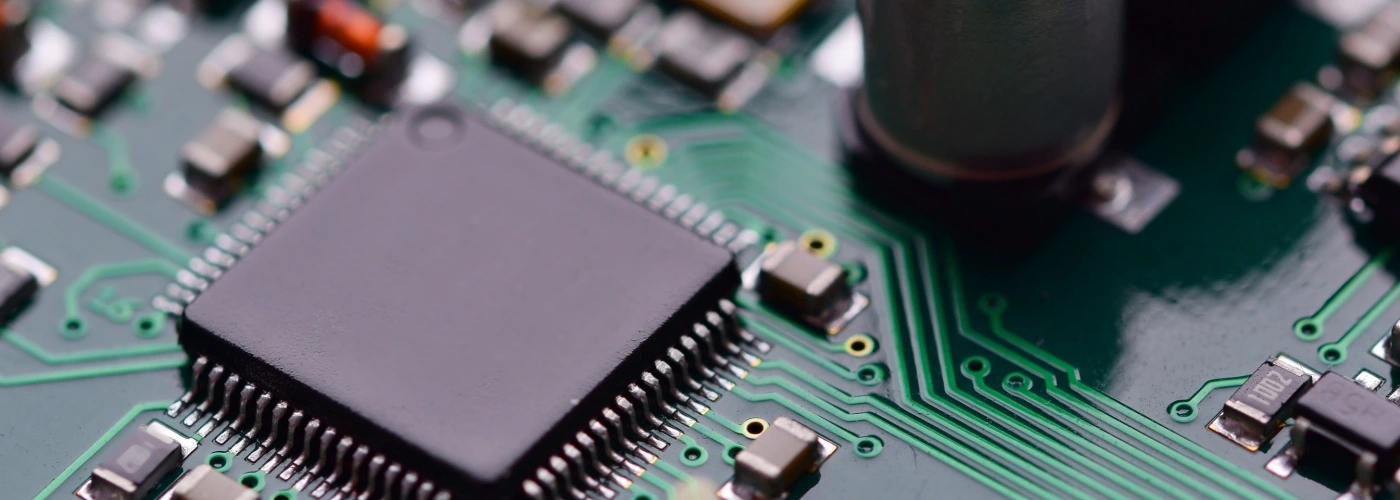

A global industrial automation leader faced a critical product sustenance challenge as the core FPGA of their revenue-generating servo drive system neared end-of-life. Customers demanded expanded analog I/O capabilities, but discontinuation risked costly overhauls and lost revenue. The company needed a seamless FPGA transition with identical functionality, new analog I/O modules, strict adherence to form factors, backward compatibility, EMI/EMC compliance, and seamless integration.

Solution

Quest Global implemented a rapid product sustenance strategy that:

Executed strategic FPGA transition to a second-source FPGA with equivalent logic elements, I/O count, memory, and package specifications

Seamlessly migrated and verified the IP core, ensuring seamless FPGA function transfer with third-party IP integration

Developed an advanced analog I/O extension module featuring an ARM Cortex M0 controller with 12-bit ADC and 16-bit timer for enhanced system capabilities

Implemented high-performance analog front-end supporting -11V to +11V, -22mA to +22mA input ranges and 0 to +11V, 0 to +22mA output ranges

Designed and optimized a 6-layer PCB layout following high-speed design guidelines for improved signal integrity and reduced electromagnetic interference

Ensured EMI/EMC compliance testing across 9 IEC standards, including ESD, radiated immunity, and magnetic field tests

Established complete manufacturing support from prototype fabrication through serial production with automated testing protocols

Delivered STM32-based firmware development, including communication protocols, I/O drivers, and backend communication systems

Results – At A Glance

Extended legacy product lifecycle, safeguarding revenue and customer investments

Created new revenue streams with analog I/O expansion modules

Ensured backward compatibility through seamless IP core migration and functionality transfer

Delivered fully validated prototype control boards, passing system testing and verification

Achieved cost optimization through optimized component selection

Implemented a smaller form factor design, adapting to standard mechanical enclosures

Passed comprehensive compliance testing across 9 EMI/EMC standards, ensuring global market accessibility