Challenge

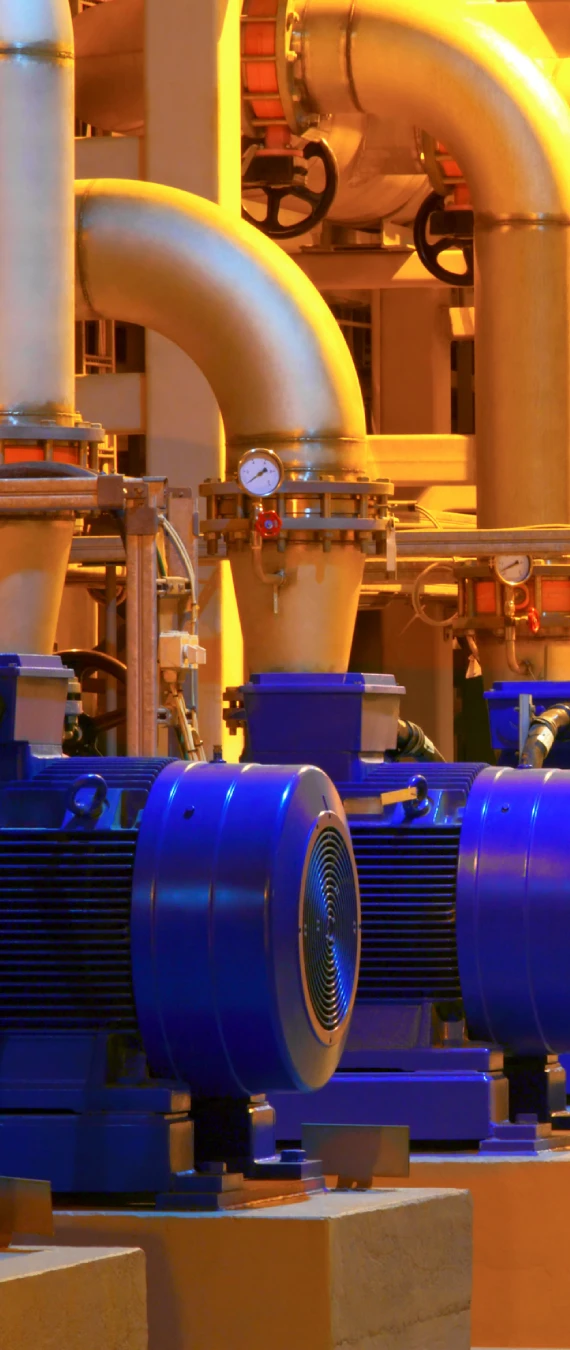

A global manufacturing leader in fluid motion control equipment supplying pumps, valves, and seals needed to upgrade their legacy and latest actuators used in demanding environments like oil & gas, chemical, and water industries at remote locations. These mission-critical systems faced power outages, causing communication loss, blind spots in system health monitoring, delayed diagnostics, costly emergency field service, and safety risks in pressure-sensitive operations.

The customer required a redesigned power backup board to support multiple actuators during outages, providing over 10 minutes of backup power, addressing part obsolescence, and ensuring full compatibility with existing installations. The project scope included prototype development, seamless system integration, comprehensive testing, and production-ready documentation—all within the physical and mechanical constraints of deployed actuator variants, maintaining their form, fit, function, and backward compatibility.

Solution

Quest Global executed a sustenance-oriented hardware redesign that delivered power-independent system status, alarm state and monitoring, enabling complete system diagnostics and safe response procedures.The team:

Designed within strict mechanical constraints, developing a compact solution that fits within the existing enclosure without altering form-fit-function across multiple actuator variants

Modified the PCB layout to meet new space and functional requirements

Migrated designs to the latest EDA tool for standardization

Validated circuit changes for compatibility and streamlined verification

Maintained full backward compatibility with multiple actuator variants

Enabled 12 minutes of power backup

Introduced additional supply voltage monitoring and controls

Conducted board bring-up and functional verification

Developed intelligent power management for line status verification, health transmission, safe shutdown, and auto-recovery

Results – At A Glance

Redesigned board doubled backup time, providing 12 minutes of power to eliminate blind spots and ensure full operation during outages

Enhanced reliability with intelligent power management and advanced monitoring

Resolved component obsolescence with cost-effective, low-complexity alternatives

Maintained revenue streams by ensuring compatibility across both legacy and new actuator variants

Achieved very high customer satisfaction with FTR delivery and seamless production integration