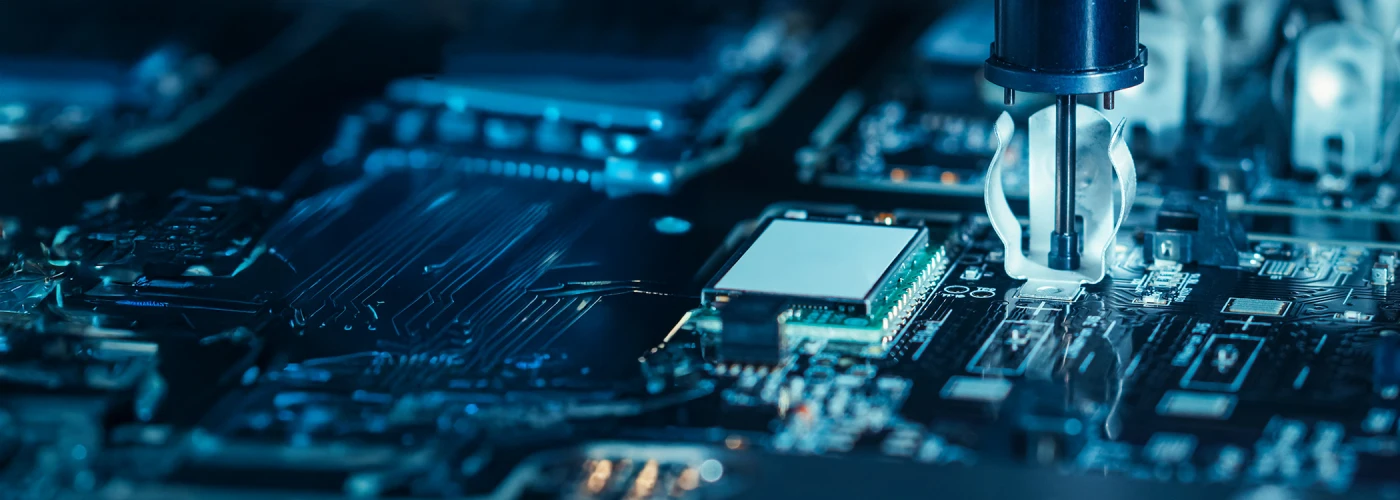

Challenge

A global industrial controls manufacturer faced critical obsolescence management challenges due to fragmented operations and ecosystems across acquired sites. Independent databases, supplier networks, and design standards led to production halts from component shortages. Overburdened R&D teams struggled with sustenance and new development, while reactive processes and a lack of early warnings heightened supply chain risks. The company needed proactive strategies and component standardization across sites without disrupting operations or compliance.

Solution

Quest Global executed an integrated obsolescence management transformation that prevented production downtime while ensuring continuous manufacturing operations across global sites. The team:

Established integrated obsolescence management for proactive monitoring and crisis resolution

Developed a cloud-based library for standardized component selection and global design synergy across global sites

BOM cleanup and optimization across 3,000+ components, ensuring cost savings and compliance

Red flag alerts for early risk detection

Executed single sourcing strategies for common parts across distributed vendors

Designed proactive monitoring with regular reviews to prevent obsolescence

Established direct manager links to ensure uninterrupted production

Delivered RoHS compliance documentation and alternatives for rapid market expansion

Launched a dashboard for real-time component lifecycle monitoring across all product lines

Results – At A Glance

Reduced production downtime to zero across all locations in 6 months

Achieved $700K in direct cost savings through component optimization using a 3,000+ part database

Reduced TCO by 15-20% through BOM optimization and supplier consolidation

Achieved RoHS certification, enabling product sales and expansion into EU markets

Achieved 60% component synergy across sites with standardized components

Freed R&D resources to focus on new product development